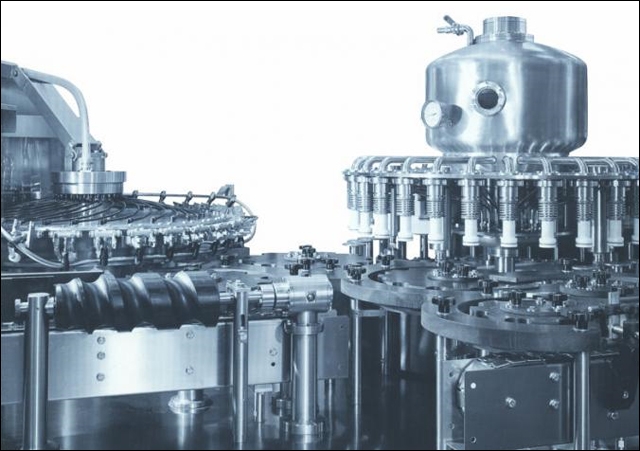

Filling Machine for Juices and Isotonic drinks

Constant filling temperature

Precise filling levels

Total recycling (also in the bottle)

User-friendly and low-maintenance

Filling machine for juices and isotonic drinks. Due to its principle of operation, it is particularly suitable for the hot-filling ( 90° ) of low- to medium-viscosity products in glass or plastic bottles. As regards size changeover, the heights of the tank and the capper can be easily adjusted to accommodate bottles of different sizes; the replacing of the bottle handling parts does not require special tools. For PET bottles, the entire unit can be designed without size changeover being required, thanks to a patented system.

|

1) Filling It is a gravity filling process which can be assisted by slight depression.Product delivery only takes place if the bottle is present; once filling has been completed, the product present in the filling tube flows into the recycling unit and is sent back to the product tank. |

|

2) Crowning The monoblock may be supplied with a crowner unit for crown caps, screw caps or other types of bottle closures.Versions equipped with more than one closing turret on the same machine are available on request. |

|

|

3) Recycling system This system, which keeps the filling temperature constant, is always in operation. Thanks to the special HOT JET valve the contents in the bottle are recycled. |

|

|

4) Sanitation The tank, filling valves and other product contact parts are mirror-polished and slightly tilted in order to safeguard against dirt and residue and to facilitate washing and draining. These parts can be washed and sanitized using hot or cold liquid solutions. |