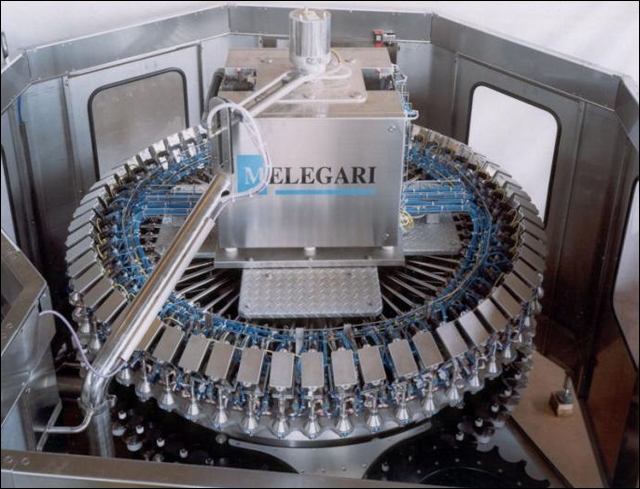

Electronic Volumetric Filling Machine for Alcoholic products

Highly precise filling performance (±0.5% of rated volume)

ULTRA CLEAN filling

User-friendly and low-maintenance

The VOL JET ALCOHOL system, which is designed to process all types of containers, is constructed with flow rate gauges for each filling valve. The special filling method, which does not require contact between the bottle and the filling valve, avoids all vertical movements of the latter, with the following important advantages: elimination of wear-related problems, elimination of the need for frequent maintenance and extremely efficacious sanitation cycle.

|

1) No contact between filling valve and bottle This special type of filling valve has been researched and developed so as not to require contact between bottle and filling valve, thereby guaranteeing scrupulously high and constant levels of hygiene. |

|

2) Filling This is controlled by individual flow rate gauges, each fitted to its respective delivery valve, through which the quantity of product to be poured into the bottle is dosed with extreme precision. |

|

3) Monitoring The constant transmission of data between valves and flow rate gauges is managed by a PLC at the centre of the machine and made to rotate by it.The work cycles can be controlled from the operator panel, on which up to 99 production job files can be set. |

|

4) Sanitation This phase, which is completely automatic, is set from the operator panel and controlled by the PLC.To safeguard against dirt and residue and to facilitate washing and draining, the surfaces are mirror-polished and slightly tilted. |