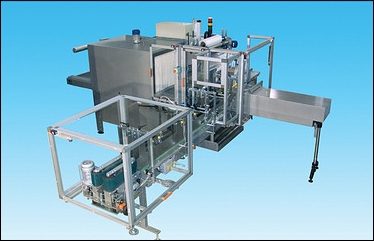

Automatic machines with feeder positioned at a right angle, either to wrap single products or to group them in bundles that will be subsequently wrapped by film and heat shrunk.

Various versions are available according to production requirements.

Production rate: 5-12 bundles per minute.

• Single or multi-track conveyor for product infeed according to pack diameter and layout, placed at a right angle with respect to the wrapping machine.

• Upper & lower reel holding unit with motor-driven unwind system including a set of idle pulleys and jockey rollers for automatic control of film unwinding.

• Sealer unit, with “industrial” type hot bar, piloted sideways by steel cylinders and moved pneumatically

• Sealing temperature controlled by thermoregulator and sealing time controlled by proper timer in control board.

• Tunnel conveyor in steel wire netting (or slats coated with a silicone sheath) equipped with mechanical variable speed gearmotor for adjusting the conveying speed.

• Heat shrink chamber, duly insulated through mineral wool, equipped with suction fan and further uniform recirculation of the air around the pack in a closed circuit. A set of finned heat resistors provides for air heating. Their location allows quick replacement during maintenance. Air can be directed both sideways and towards a central position under the tunnel, by means of special baffles according to a variety of problems that can arise during shrinking cycle.

• Tunnel heat regulation by means of thermostat limiting consumption, once the operating temperature is reached.