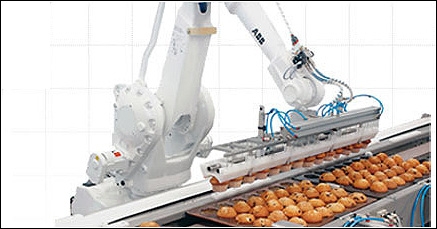

IRB 2400 is an anthropomorphic industrial robot ABB, with 6 axis.

It is mainly used for cartoning, or in general for product pick & place operations, especially when it is necessary to handle many components at the same time. It is actually available in 3 versions, with a managing capacity from 5 up to 16 Kg.

Thanks to its operating field, it can be used on more pick and-place stations.

Thanks to the ABB S4C+ robot control its versatility is also particularly enhanced by using the conveyor tracking functionality.

This functionality allows the robot to operate on moving elements, thus offering more freedom during the layout planning phase and during the design of the plant.

Thanks to the ABB S4C+ control, the IRB 2400 can be inserted into packaging lines, communicate with other devices and be interfaced with the ABB vision system, the PickMaster.

Thanks to the PickMaster software and to Cognex technology, the robot can pick up the products from the transport system while moving, deposit them on the moving trays or blisters and manage in real time the distribution of the load among many robots.