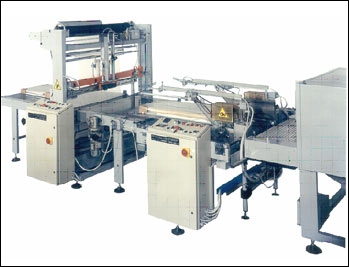

They can be equipped either with wrapper feeder and shrink tunnel assembled on one single frame – which results to be more compact and economic – or with separated shrink tunnel for packing big-sized products. Can be equipped with 700÷2700-mm. sealing bars, according to measurements of product to be wrapped.

Version with continuous side sealing system is available, for complete closure of package.

• Feeder consists of a motor-driven belt conveyor in line with the wrapping machine. It can be loaded with products either manually or automatically from upstream line.

• Upper & lower reel holding unit with motor-driven unwind system including a set of idle pulleys and jockey rollers for automatic control of film unwinding.

• Sealer unit, with “industrial” type hot bar, piloted sideways by steel cylinders and moved pneumatically.

• Sealing temperature controlled by thermo-regulator and sealing time controlled by proper timer in control board.

• Product conveyor in steel wire netting, equipped with mechanical variable speed gear-motor for adjusting the conveying speed.

• Heat shrink chamber, duly insulated through mineral wool, equipped with suction fan and further uniform recirculation of the air around the package, in a closed circuit. A set of finned heat resistors provides for air heating. Their location allows rapid replacement during maintenance. Air can be directed both sideways and towards a central position under the tunnel, by means of special baffles according to a variety of problems that can arise during shrinking cycle.

• Tunnel heat regulation by means of thermostat limiting consumption, once the operating temperature is reached.